The microdisplay, reinvented.

From powering pixels to laser projection.

Engineered for scale, reliability, clarity, and affordability.

Numunon replaces millions of powered pixels with a single micro-mirror and three RGB lasers that project light directly, resulting in higher efficiency and lifespan.

How it works:

Lasers project the light

Three RGB lasers generate pure color

MEMS mirror steers it

Millions of light dots at >120Hz.

The image is formed

Brighter, sharper and higher color brilliance

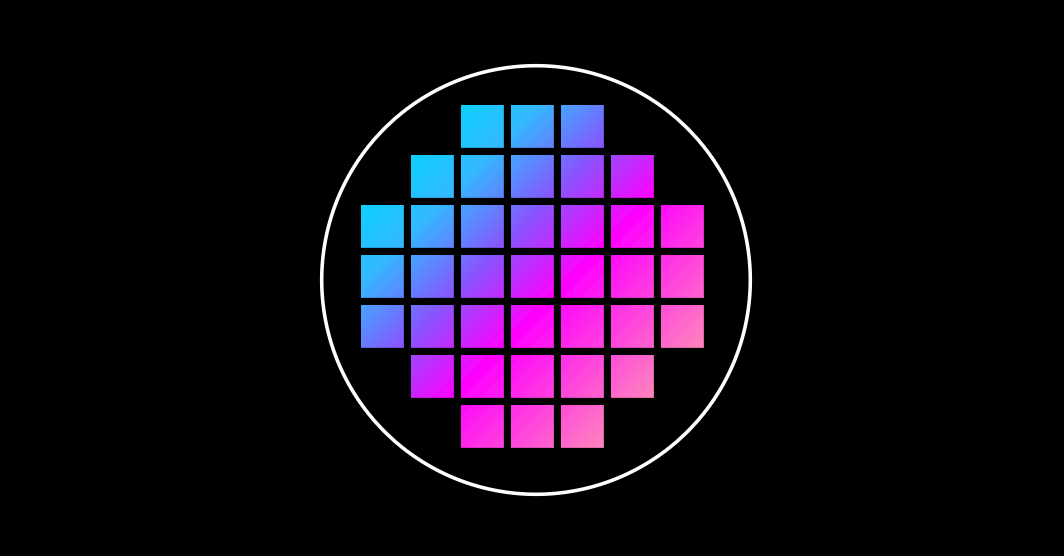

Traditional microdisplays

Emitting light

Uses millions of microscopic light elements called “pixels”

Every pixel must be continuously driven to make an image

More brightness = more power, more heat, and reduced lifespan

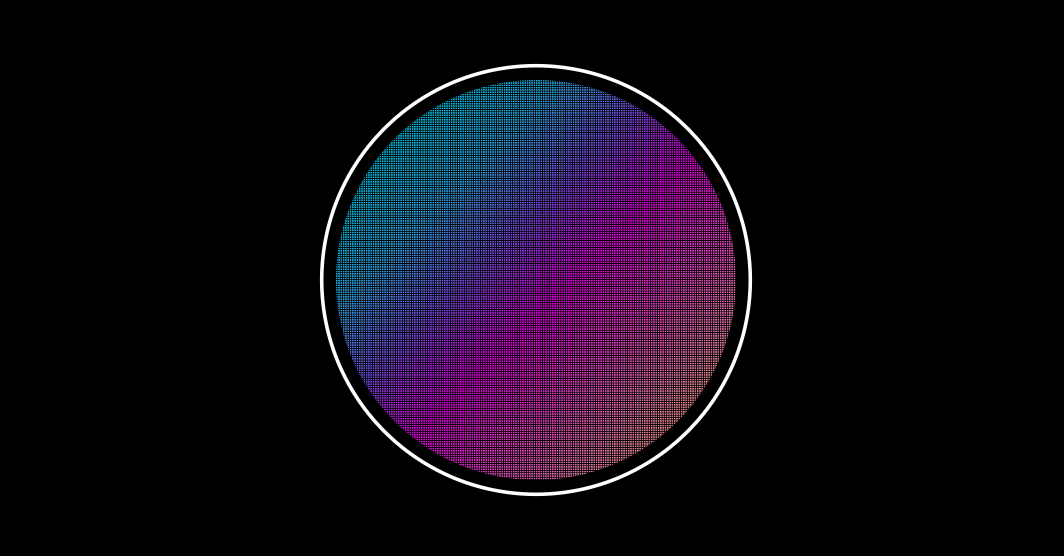

Numunon microdisplays

Laser projection

Uses laser beams steered by microscopic mirrors

Light is projected only where it’s needed

Produces less heat, lasts longer, and consumes less power

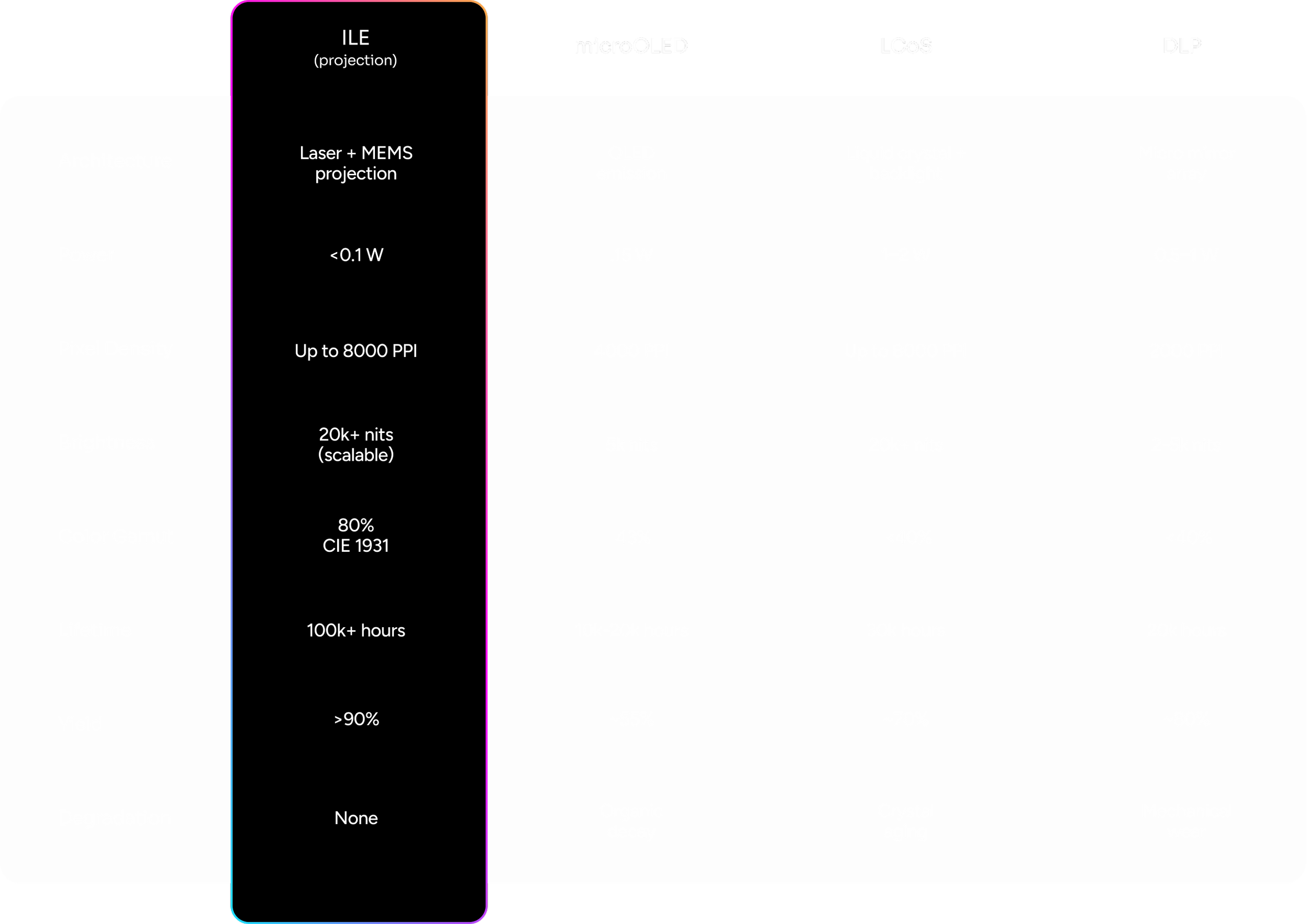

Comparison

Performance advantages:

The manufacturing difference:

Built to scale

-

microOLED is a fragile, yield-sensitive technology stack. It depends on oxygen/moisture-sensitive organic films that require stringent encapsulation and ultra-clean manufacturing. At the brightness levels XR needs, thermal and aging constraints tighten quickly, and scaling high-PPI production is expensive because yield and defect sensitivity dominate cost. Supply is concentrated in a small number of overseas fabs, making capacity and lead times hard for OEMs to control.

microOLED

-

MEMS is “mechanical”, built from silicon using trusted processes. These are the same used for microchips for phones, cars, and medical devices. These factories already exist throughout the United States.

Existing facilities support the processes required by our technology. High yields, low cost, made with equipment and expertise America already leads in.

MEMS

MEMS manufacturing benefits

Semiconductor Manufacturing

Made with the same processes as traditional semiconductors

High-Yield Production

Repeatable, and cost-effective at scale

Heat and shock resistant

Built for extreme conditions

Made in the USA

No foreign supply risk or fragile materials

Drop-in replacement.

Numunon’s microdisplays fit directly into existing AR, VR, XR and other optical systems. Same footprint. Same interface. Superior performance.

Familiar Geometry

Fits current module dimensions and alignment tolerances

Optical Compatibility

Designed for compatibility with existing waveguides, lenses, and combiners

Scalable Form Factor

Compact footprint supports multiple display sizes and configurations

Learn more about Numunon and the people behind it.

Join the future of display technology:

Partner with us